We’re all fired up at Young’s Equipment GRILL CENTRAL about smoking hot deals on Louisiana® and PitBoss® Grills and Smokers. We have a host of exciting new products that will help you make the most of your next culinary adventure. Look at the Black Label Louisiana® Grill series for example. The list of impressive features seems to never end so come to your nearest Young's Equipment store and find out for yourself!

The list goes on and on so why not experience it for yourself? Make the most of your leisure time with a new grill from Young's Equipment!

Visit your nearest Young's Equipment today!

At Young’s Equipment we are committed to helping you feed the world! That is why we have developed a complete selection of primary and secondary Air Seeder Hose to get your seeds from the tank to the soil where it all begins. Young’s Equipment is your air seeder hose source for all brands including Bourgault® and Vaderstad®/Seedhawk®. We are fully stocked and ready to meet your Air Seeder Hose needs and you can be sure to receive exceptional service at any of our nine locations. Contact one of our Parts Professionals to discuss your air seeder hose requirements today.

Kanaflex® polyurethane lined primary hose is available in red or black and offers superior flexibility, it is light weight and resistant to abrasion and protected from UV degradation.

Kanaflex® PVC primary hose has excellent abrasion resistant qualities and UV protection. Available in white or black.

EVA plastic tubing is available in 3 sizes. 7/8”, 1”, and 1.036”. Our Parts Teams will be happy to assist you in finding the right size for your air seeder.

The field conditions followed by the harsh winter takes a toll on all hoses on your machine, not just the seed and fertilizer runs. Now is the best time to check the hydraulic hoses as well. And once again Youngs Equipment has you covered. Each of our locations is fully stocked and equipped to provide custom made hydraulic hose from 1/4" to 1" double braid that is far superior to OEM hoses. Our wide selection of fittings is ready to meet your needs during pre-seeding maintenance as well as to get you going again when the unexpected occurs. You can count on us!

Being prepared is your specialty. You know as well as anyone that when it is go time the preparations you make now will save you time, frustration, and expense. Does your drill have the same hydraulic hose repeated for each opener? Don’t let a blown opener hose stop you. Keep a few spares on hand and save the extra road trips when you could be in the field.

In addition to air seeder and hydraulic hose, at Youngs Equipment we have hose for many other applications. From heater hose and fuel line to water discharge and vinyl tubing with or without nylon braid. Whatever your hose needs are, we are ready to help keep you growing!

Visit your nearest Young's Equipment today!

Your Young’s Equipment Team

We are proud to be able to introduce the MyYoungsEquipment customer portal to you, the around-the-clock access to your account and equipment information. MyYoungsEquipment is a web-based tool that provides real value at no cost to you and your operation. Your MyYoungsEquipment access gives you a sleek, modern and easy to use interface with a secure environment. All of your information with Young's Equipment is at your fingertips and editable anytime.

In the “My Equipment” section we store valuable information about your machines. Information that is shared with only our staff and can be updated by you or us anytime. If you acquire a new treasure you can easily add it to your MyYoungsEquipment profile or if you no longer own it, remove it, which makes your conversation with us much easier when it comes to service for your machine and the processes more fluent.

Start the year with a bang at your Young’s Equipment store, with your opportunity to use top of the line lubricants in your equipment and save cold hard cash while doing it. We are proud to be able to introduce the Viscosity Oil line of lubricants to you.

For decades Viscosity Oil has supplied CNH with high end lubricants formulated specifically for CaseIH equipment. Young's Equipment's strong partnership and history with Viscosity Oil means we now have the opportunity to cut out the middle man and get the lifeblood of your machine directly from the supplier. For you as our partner in business that means significant cost savings which we are happy to pass along to you for the same high quality product you know, have always used and trusted. What's more important is that it doesn't matter what colour equipment you run, you’ll be able to use our Viscosity Oil products in every make and model of all agricultural and construction equipment you have on your farm.

But we won’t stop there, we’re constantly working on providing solutions for your farm that make a difference and add additional value you can’t get anywhere else. In 2021 we are working towards on-farm-delivery of bulk lubricants and DEF and hassle-free storage solutions that will save space in your shop and up-to-date ways to communicate your lubricant demand directly to us. Please stay tuned for that and make sure you follow our social media accounts where you will always get the newest information about promotions and all of the different specials we offer all year long.

Next time you stop in for oil, ask our team for Viscosity Oil products and get the best price for top of the line performance lubricants. Our Parts Professionals are looking forward to telling you all about it.

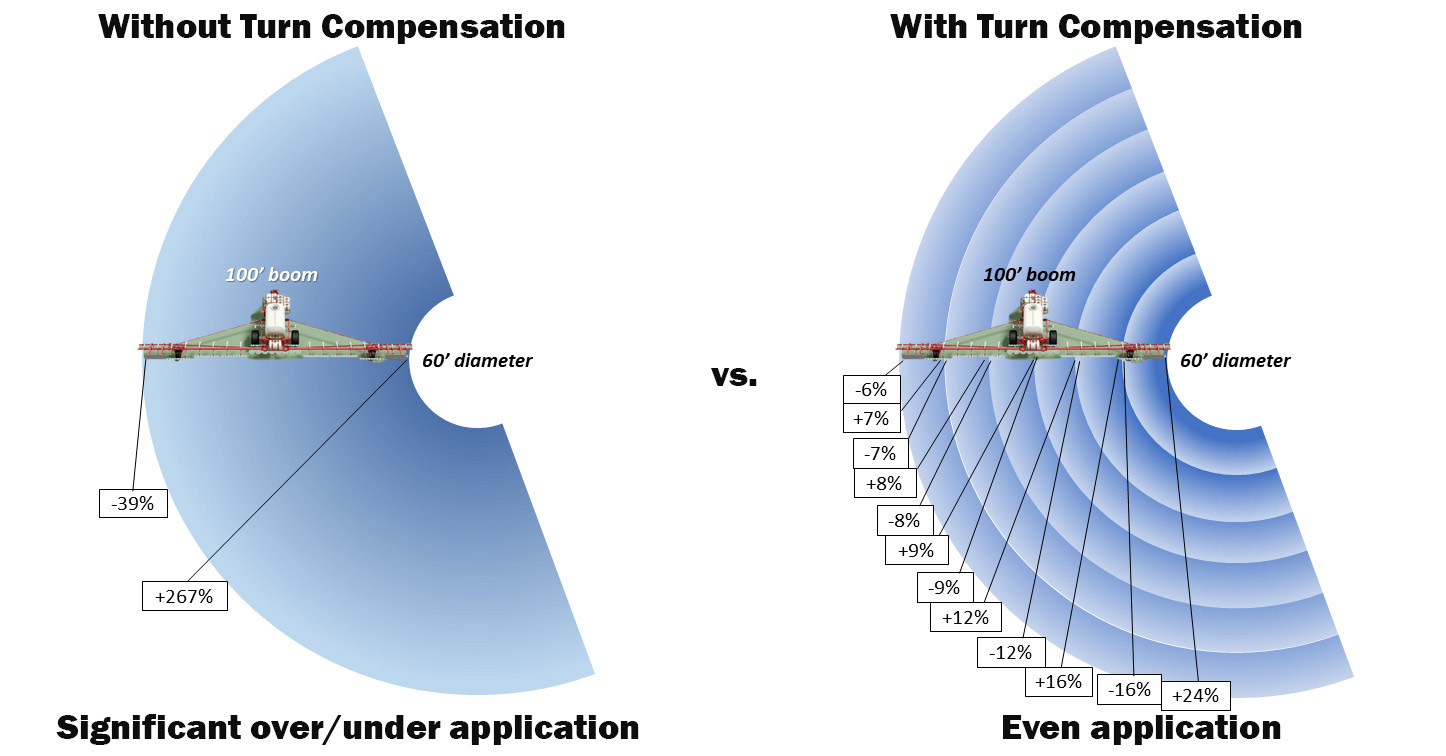

Today we have good news if your Sprayer is equipped with Aim Command spray system. We have an affordable upgrade to add Turn Compensation by section to your current machine. This system can be added to standard spray systems as well. This upgrade does not apply to sprayers with Aim Command Pro and Aim Command Flex as they already have Turn compensation. The Capstan EVO Upgrade offers you the well-known consistency in performance of pulsing nozzle technology, takes care of over and under-application within turns through sectional turn compensation. Its intuitive in-cab interface offers you real-time system feedback and diagnostics per module.

On an uncompensated boom the outermost nozzle is underdosing 39% and the innermost nozzle overdosing by 267%. Repeated year after year this will lead to avoidable weed problems. Young’s Equipment has the right products to take care of this problem for you, as well as the qualified technicians to install them for you. Take advantage of affordable products and no-hassle installation, our Product Specialists will be happy to answer all your questions and quote a solution tailored to your needs.

With the harsh temperatures winter in Saskatchewan throws at us, we thought now would be the perfect time to share some cold weather operating tips for your equipment. No matter which Young’s Equipment location you live closest to, you’re blessed with cold and snowy weather that is hard on your machines. The following five tips will help keep your machines running at top performance when the mercury retreats into that little bulb at the bottom of the thermometer.

In case you have further questions about winter operation, the Winter Inspections program or Hy-Tran SSL, the Parts and Service staff in all our locations will be happy to answer them for you. We are looking forward to hearing from you soon!

Accidents can happen faster than you think, one small mishap and your MacDon header might look like the one above. If this happens to your equipment, Young's is here to help. We have the expertise, the tools and the unique specialty equipment to straighten and repair your header.

This offer is available for your operation, no matter what colour equipment you run as well as insurance companies throughout the province. Don't hesitate, give your local Young's Equipment Service Department a call or have your insurance adjuster call us.

Young's Equipment, Saskatchewan's top MacDon dealer, is here to help.

We have the Professionals and the parts to make sure your Header runs at peak performance this season. We would love to help you harvest more of what you grow, and do it quicker. Our Header Inspection Program is the ideal opportunity to be ready for Go-Time and ensure your Header gives you the top results you expect.

And why not get it done for the best price of the year during our 2019 Header Inspection Program? Here's are the Inspection prices we're happy to offer you:

Call or come in to any of our nine locations to learn more about our Header Inspection Program, our Service Managers and Service Advisors will be happy to answer all your questions. And while you're at it, ask us about

Two essential products that are designed to optimize your Header's performance. We're looking forward to seeing you soon.

The Never Spill Spout in action: You can fill trucks and bins without needing to climb ladders to constantly check how full it is! The Never Spill Spout sounds an alarm when your bin is full, preventing spillage! Never offerfill a bin again! Never plug another auger! No need for individual bin indicators! Never spill another bushel!

Stay in the truck, move up as the alarm sounds, and fill your truck front to back by yourself with ease.

New Model "NO Snag Spout" NOW AVAILABLE! The spout is bright orange to increase visibility at night! Also now the Never Spill Spout includes 2 alarms for even more volume!