Contact your local Young's Equipment Parts Department for more information.

Back by popular demand - Our 3-month sale on bulk lubricants and filters is back! This year it's more important than ever to get your equipment ready for action as soon as possible. Act early to maximize your savings!

We kick things off on February 1st with 15¢/L saving on all Bulk oils and 15% discount on all filters.

In March we drop to 13¢/L saving and 13% discount on filters.

April will be 10¢/L saving and 10% discount on filters.

Choosing OEM filters from CNH Industrial is a smart investment that can help maximize the performance, reliability, and longevity of your equipment, ultimately contributing to greater efficiency and profitability for your business. Have a look at the info graphic and videos below to see some important differences between Case and all makes filters.

Overall, the combination of OEM quality and discounts makes it an opportune time to choose filters from CNH Industrial. By taking advantage of these offers, you can enjoy all the benefits of OEM filtration at an even more attractive price point, ensuring optimal performance, reliability, and cost-effectiveness for your equipment and business operations.

As further incentive, we are excited to extend a special offer to you. By purchasing 100 liters of oil from us, you can secure an exclusive 15% discount on all filters for the remainder of the year.

To take advantage of these offers or to learn more, please contact our Parts team at your favorite Young's location. We are eager to assist you with any questions you may have and thank you for your continued trust and partnership.

We are looking forward to seeing you soon!

Take advantage of special FCC rates for new and used air drills, tanks, planters, and all other pull-type equipment.

Offer effective from December 1, 2025, to February 28, 2026.

ELIGIBLE PRODUCTS

NOTES

At Young’s Equipment we’re all about going the extra mile for you, about getting you going out in the field every day and making sure your operation runs as smooth and uninterrupted as possible. Inspecting and protecting your equipment is a vital part of what we do, and every year around this time we go to great lengths to offer you the highest value and top professional service that will make sure your machines are ready to go for the next growing season.

Our two different inspection levels are designed to meet and exceed your expectations, whether you choose our Value Visual Inspection or our most popular Premier Inspection, you'll find the right inspection for all your equipment at Young's.

But that’s not all, we would like to invite you to benefit from the Young’s Equipment Loyalty Program that gives you a $100 Gift Card for every machine you bring in that was inspected the previous year and one free header inspection when you book three inspections as well. In addition to that you will receive 10% Discount on all parts installed as part of your inspection! Get the best value for the most affordable pricing.

We go above and beyond with not only our exceptional service quality and the benefit of our extensive inspection checklist to check the parts that even our competitors miss, but also with our unique premier electronic inspection services. Let us handle your inspection work while you prepare for next year’s seeding plans. We can electronically send your inspection details to you, anytime, anywhere in the world.

If you haven't done so already, give us a call so we can go over all the details and answer any questions you may have. Our Service Advisers and Service Managers are available for you and are happy to answer all your questions.

When the conversation comes to Grain Bags, top of the line quality means something different to everybody. Some folks value a grain bag made out of multiple layers, some value unprecedented grain bag thickness.

Unprecedented 9.5 mil thickness ensures ultimate durability in the most extreme conditions. Available in lengths between 150 and 300 feet. Manufactured by HITEC.

Let us know if you have any questions about Grain Bags, our Parts Professionals in any of our locations will be happy to answer them for you and find the best solution for your specific needs. And please keep in mind, quantities are limited!

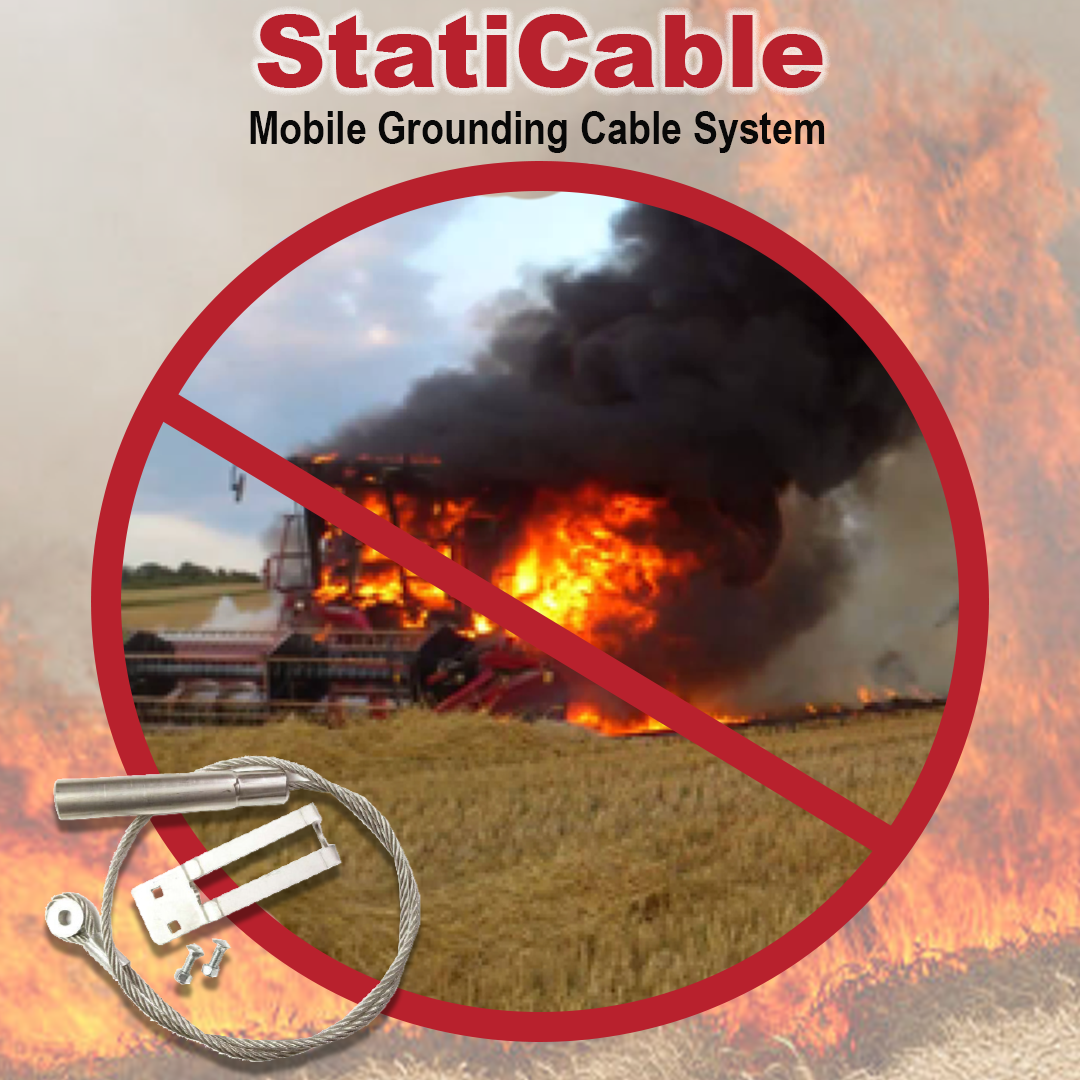

A little preparation can go a long way, when it comes to preventing loss from fires in your fields and damage to your equipment. Youngs Equipment has everything you need to protect your investments. Click any of the pictures for more information on the product.

Mobile Grounding Cable System

A combine fire can be catastrophic, costing you hundreds of thousands in lost crop and expensive equipment, and eating away your scarce harvest time. When the air is dry and temperature is just right, static electricity can build to dangerous levels on your equipment. This can cause sparks, igniting chaff and grain dust in the combine. Creating a proper path to ground with a Staticable can be significantly lower this risk. #STATIC The STATICABLE is a cost-effective solution to help control static-causing combine fires.

Use a blower regularly to remove flammable materials from all areas of the combine. With speeds up to 765 CFM, EGO and Milwaukee blowers have the power to get the job done!

Starting at $219.99

H2O Fire Pro has a 40 US gallon tank and a 5 GPM pump to fight fires and hot spots in the field. Includes a 25’ hose assembly and a built in hose reel. Can be mounted to grain carts, service trucks, ATVs, Side by Sides, etc. with straps or built in threaded inserts.

Having a 2.5-gallon water filled fire extinguisher in every piece of equipment is a must and the H2O Fire Pro nearby can save your crop or at the very least, buy precious time before fire crews arrive.

#26006-78 - H2O Fire Pro

#WBDLABC10WH - Strike First ABC Fire Extinguisher With Wall Bracket, 10 lb

#WBPW250 - Strike First Pressurized Water Extinguisher, 9-1/2 lb|2-1/2 gal

#HDVB3 - Wall Bracket

A portable electric device for taking samples of your crop. This self-contained unit comes with 4 interchangeable concaves, a lithium-ion battery and a variable-speed brushless motor. Samples collected are identical to a combine giving you the perfect sample size for moisture content tests and quality analysis.

Mosquito Barrier is a very strong liquid garlic spray for mosquitoes made from very potent garlic cloves. Garlic has a natural sulfur which repels mosquitoes. Spraying garlic to keep insects away is not something new, farmers and master gardeners have been doing it for many generations.

Since mosquitoes are soft-bodied insects the garlic juice can be very toxic to them in increased concentrations. The juice does not harm humans, pets or plants, but to mosquitoes it can be deadly. The odor of sprayed garlic juice becomes undetectable to humans within minutes, but mosquitoes can detect odor as much as 10,000 times better than a human, so even though you can't smell the garlic, they can and they will stay away from the sprayed area for up to a month or longer. Additionally, Mosquito Barrier, when mixed with canola oil, coats any standing water in the area with a very thin film of natural oil. This oil suffocates the mosquito larvae which can develop in standing water.

Unlike harmful chemicals, Mosquito Barrier is a natural insect repellent that doesn't kill bees or butterflies and is completely safe for children, fish, birds, dogs, cats and other pets. Be careful of traditional chemical pesticides, they can kill more than mosquitoes.

Generally, four applications are enough for the entire mosquito season. Even in the heaviest of infestations the gallon size is almost always enough for the entire year for most homes.

With all this wonderful rain comes mud. To mitigate frustrating down time we keep a variety of tow straps in stock so before you find yourself stuck in the field or anywhere else come into Young's Equipment and pick up the tow straps you will need to pull yourself out.

Made in Western Canada, these tow straps are manufactured to perfection and tested relentlessly to ensure their safety and dependability. Using advanced state of the art equipment, every piece is tested on a pull tester and tagged with a working-load limit.

Available in widths between 4 and 12" and break strength of up to 240,000lbs, we can help you rescue whatever you've got stuck, no matter the size or color of your equipment!

Head down to your favorite Young's Equipment branch and our expert parts staff will help you pick the tow strap that's right for you.

Wishing you a safe and happy growing season.