Regina Service Department’s Pinnacle Award for meeting Case IH’s Pinnacle Service Criteria. Regina has met these requirements for the past 5 years. Pinnacle awards are presented to an elite group of Case IH dealers who have met the highest standards for facilities, training, and customer service within their Service Department. Congratulations to the Regina Service Team on this achievement.

Picture date Oct. 2020

Case IH has awarded Assiniboia Service Department their Pinnacle Award for meeting Case IH’s Pinnacle Service Criteria. Pinnacle awards are presented to an elite group of Case IH dealers who have met the highest standards for facilities, training, and customer service within their Service Department. Congratulations to the Assiniboia Service Team on this achievement.

Case IH has awarded Moose Jaw Service Department their Pinnacle Award for meeting Case IH’s Pinnacle Service Criteria. Moose Jaw has met these requirements for the past 4 years. Pinnacle awards are presented to an elite group of Case IH dealers who have met the highest standards for facilities, training, and customer service within their Service Department. Congratulations to the Moose Jaw Service Team on this achievement.

Case IH has presented the Weyburn Service Department’s Pinnacle Award for meeting Case IH’s Pinnacle Service Criteria. This is the second year in a row Weyburn has met these requirements. Pinnacle awards are presented to an elite group of Case IH dealers who have met the highest standards for facilities, training, and customer service within their Service Department. Congratulations to the Weyburn Service Team on this achievement. Accepting the award is On the left. Paul Mansfield. Service Manager. Center, Broc Racine Foreman and on the right, Dylan Bachelu Service Technician.

Congratulations to the Service department at Young's Equipment in Davidson for once again achieving Pinnacle status with Case Ih . Pinnacle status is achieved by meeting the highest standards for facility, training and customer service within the department. To achieve Pinnacle status with Case Ih is only achieved through hard work and an entire team effort. Thanks to all that continue to strive to be part of this elite group.

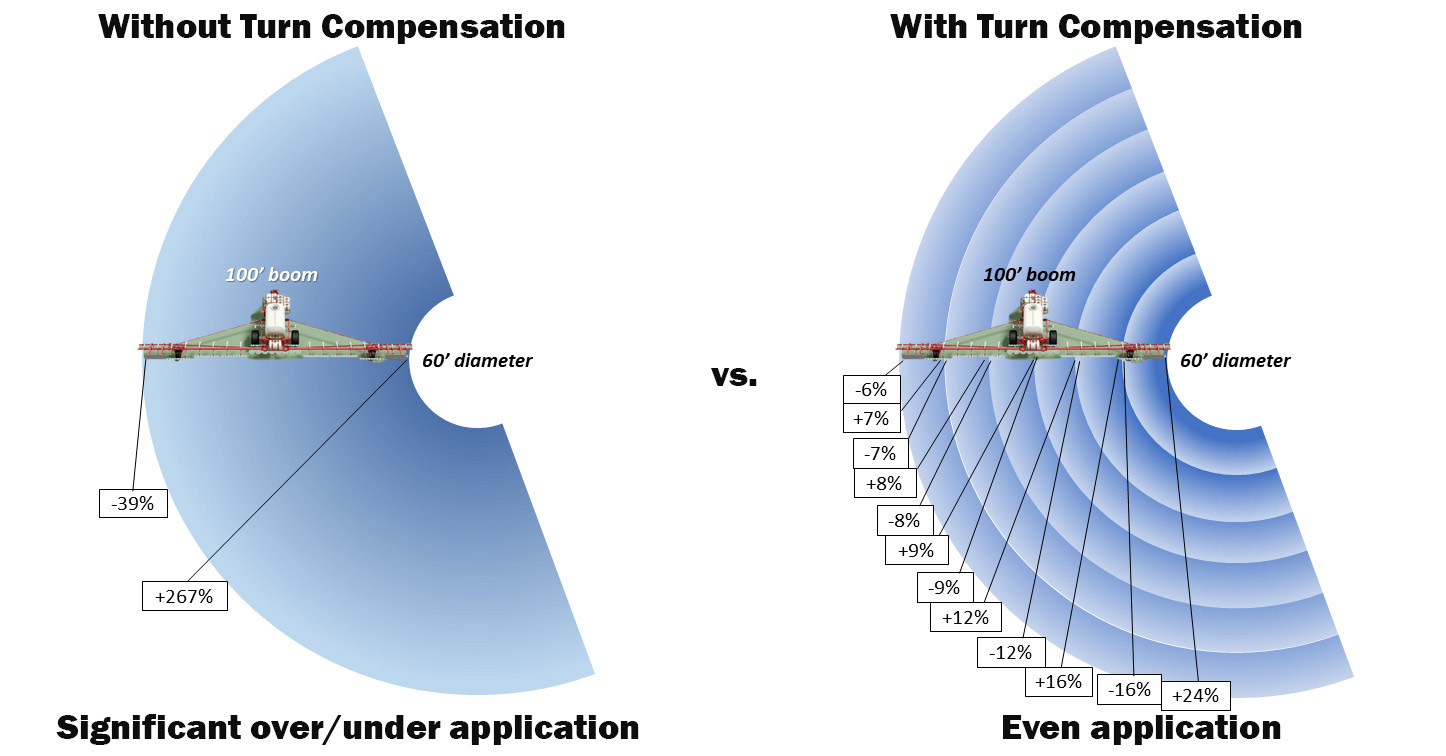

Today we have good news if your Sprayer is equipped with Aim Command spray system. We have an affordable upgrade to add Turn Compensation by section to your current machine. This system can be added to standard spray systems as well. This upgrade does not apply to sprayers with Aim Command Pro and Aim Command Flex as they already have Turn compensation. The Capstan EVO Upgrade offers you the well-known consistency in performance of pulsing nozzle technology, takes care of over and under-application within turns through sectional turn compensation. Its intuitive in-cab interface offers you real-time system feedback and diagnostics per module.

On an uncompensated boom the outermost nozzle is underdosing 39% and the innermost nozzle overdosing by 267%. Repeated year after year this will lead to avoidable weed problems. Young’s Equipment has the right products to take care of this problem for you, as well as the qualified technicians to install them for you. Take advantage of affordable products and no-hassle installation, our Product Specialists will be happy to answer all your questions and quote a solution tailored to your needs.

February 27, 2020 – Today Young’s Equipment announced an in-kind donation of $450,000 for new, state-of-the-art equipment for Agricultural Equipment Technician student and apprentice training at Saskatchewan Polytechnic.

“Young’s Equipment is a long-time supporter of Sask Polytech and the Agricultural Equipment Technician program and apprenticeship training,” says Tim Young, general manager, Young’s Equipment. “Today’s $450,000 in-kind donation of equipment for students and apprentices to learn on includes: Case IH front loader, CVT transmission, combine PTO gear box and core, CASE IH MAXXUM tractor, Case Farmall tractor and two Kubota engines.”

“Our heartfelt thanks to Tim Young and the team at Young’s Equipment for your incredible gift today, and for your continued support of our students throughout the past many years,” says Dr. Larry Rosia, Sask Polytech president and CEO. “Your gifts are integral in helping our School of Transportation train the Agricultural Equipment Technicians needed today and into the future. This donation helps Agricultural Equipment Technicians advance their careers, helps employers hire highly qualified technicians and advances Saskatchewan’s agriculture industry and economy.”

With the harsh temperatures winter in Saskatchewan throws at us, we thought now would be the perfect time to share some cold weather operating tips for your equipment. No matter which Young’s Equipment location you live closest to, you’re blessed with cold and snowy weather that is hard on your machines. The following five tips will help keep your machines running at top performance when the mercury retreats into that little bulb at the bottom of the thermometer.

In case you have further questions about winter operation, the Winter Inspections program or Hy-Tran SSL, the Parts and Service staff in all our locations will be happy to answer them for you. We are looking forward to hearing from you soon!

Congratulations to Travis Block, Dylan James, Rodney Eisen, and Zachary Fisher (missing in photo) for recieving Apprenticeship Awards for exceptional achievement in their Journeyperson and Apprenticeship Level Agricultural Equipment Technician exams, meeting scholarship requirements of Young’s Equipment Inc. & the Western Equipment Dealer Association.

Accidents can happen faster than you think, one small mishap and your MacDon header might look like the one above. If this happens to your equipment, Young's is here to help. We have the expertise, the tools and the unique specialty equipment to straighten and repair your header.

This offer is available for your operation, no matter what colour equipment you run as well as insurance companies throughout the province. Don't hesitate, give your local Young's Equipment Service Department a call or have your insurance adjuster call us.

Young's Equipment, Saskatchewan's top MacDon dealer, is here to help.